Technology that rewrites the standards

Hyaluronic acid is a molecule found naturally in the body: it is vital for hydrating the skin, keeping it toned and elastic and boosting regeneration and repair.

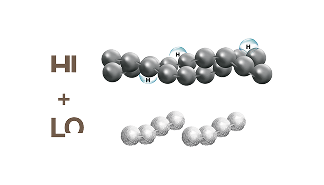

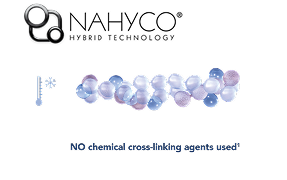

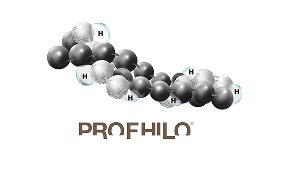

In 2015 IBSA Derma patented a thermal process that combines high and low molecular weight hyaluronic acid chains, without using chemical reagents. This produces cooperative hybrid complexes of hyaluronic acid in high concentrations. All this lies at the core of NAHYCO® Hybrid Technology.